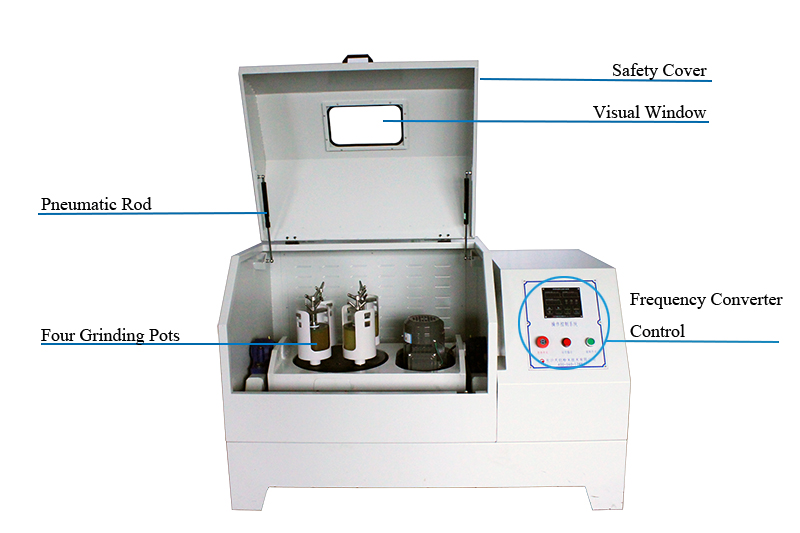

Overview of Laboratory Full-directional Planetary Ball Mill

On basis of vertical planetary ball mill, the omnidirectional planetary ball mill adds the function of planetary disc overturning. While planetary disc and mill jars are doing planetary movement, they can also do 360 degree overturning in a stereo space to realize multi-directional and multi-dimensional movement of ball mill jars, and to improve degree of disordered movement of balls and materials. All material are ground inside the mill jars without dead angle, which makes grinding materials more uniform and finer. This kind of ball mill solves common issues such as sinking to the jar’s bottom and sticking to the jar’s wall.

QXQM series planetary ball mill has four ball grinding tanks installed on one disc. When the turn disc rotates, the mill pots revolve on their own axis and make 360 degree rotation. And the balls in the tanks grind and mix samples in high speed movement. The product can smash and blend various products of different materials and granularity with dry or wet methods. Minimum granularity of ground samples can be as small as 0.1 micron meter. It is widely used in the fields of Geology, Mining, Metallurgy, Electronics, Construction Material, Ceramics, Chemical Engineering, Light Industry Medicine, Environmental Protection etc.

Features of Tencan Laboratory Full-directional Planetary Ball Mill

| Technical Features of Laboratory Full-directional Planetary Ball Mill | |

| Drive Mode | Gear drive |

| Operate Mode | Two or four mill jars can be used for each grinding |

| Maximum Loading Capacity | Less than 1/3 of each jar volume Total max capacity: less than 1/3 of total jars volume |

| Feeding Size | Soil material≤10mm,other materials≤3mm |

| Output Granularity | Smallest granularity can be achieved to 0.1μm |

| Rotational Speed Ratio | 1:2 |

| Max.Continuous Operating Time | 48 Hours |

| Materials of Jar | 304 Stainless steel, 316l stainless steel, Zirconia, Nylon, PU, Alumina ceramic (corundum), PTFE, Agate, Tungsten carbide |

Table 1 Technical Parameters For Laboratory Full-directional Planetary Ball Mill

| Model No. | Specifications | Matchable Sizes of Mill Jars |

Matched Quantity | Matchable Sizes of Vacuum Mill Jars |

| QXQM-0.4 | 0.4L | 50ml, 100ml | 4 pcs | 50ml |

| QXQM-1 | 1.0L | 50ml, 100ml, 250ml | 4 pcs | 50ml. 100ml |

| QXQM-2 | 2.0L | 50ml-500ml | 4 pcs | 50ml, 100ml, 250ml |

| QXQM-4 | 4.0L | 250ml-1000ml | 4 pcs | 50ml-500ml |

| QXQM-6 | 6.0L | 1L-1.5L | 4 pcs | 50ml-1000ml |

| QXQM-8 | 8.0L | 1L-2L | 4 pcs | 500ml-1500ml |

| QXQM-10 | 10.0L | 1L-2.5L | 4 pcs | 1L-2L |

| QXQM-12 | 12.0L | 1L-3L | 4 pcs | 1L-2L |

| QXQM-16 | 16.0L | 2L-4L | 4 pcs | 1L-3L |

Table 2 Technical Parameters For Laboratory Full-directional Planetary Ball Mill

| Model No. | Voltage | Power | Rotation Speed | Noise |

| QXQM-0.4 | 220V-50Hz | 0.75KW | 90-870 rpm | Less than 60db |

| QXQM-1 | 220V-50Hz | 0.75KW | 70-670 rpm | Less than 60db |

| QXQM-2 | 220V-50Hz | 0.75KW | 70-670 rpm | Less than 60db |

| QXQM-4 | 220V-50Hz | 0.75KW | 70-670 rpm | Less than 60db |

| QXQM-6 | 220V-50Hz | 0.75KW | 70-670 rpm | Less than 60db |

| QXQM-8 | 220V-50Hz | 1.5KW | 70-580 rpm | Less than 60db |

| QXQM-10 | 220V-50Hz | 1.5KW | 70-580 rpm | Less than 60db |

| QXQM-12 | 220V-50Hz | 1.5KW | 70-580 rpm | Less than 60db |

| QXQM-16 | 380V-50Hz | 3.0KW | 60-510 rpm | Less than 60db |

Table 3 Technical Parameters For Laboratory Full-directional Planetary Ball Mill

| Model No. | Speed Control | Net Weight | Net Dimensions |

| QXQM-0.4 | Frequency Control | 136kgs | 900*570*670mm |

| QXQM-1 | Frequency Control | 317kgs | 1330*770*850mm |

| QXQM-2 | Frequency Control | 317kgs | 1330*770*850mm |

| QXQM-4 | Frequency Control | 317kgs | 1330*770*850mm |

| QXQM-6 | Frequency Control | 317kgs | 1330*770*850mm |

| QXQM-8 | Frequency Control | 420kgs | 1360*850*930mm |

| QVQM-10 | Frequency Control | 420kgs | 1360*850*930mm |

| QXQM-12 | Frequency Control | 420kgs | 1360*850*930mm |

| QXQM-16 | Frequency Control | 550kgs | 1530*940*1100mm |

Working Priciple of Laboratory Full-directional Planetary Ball Mill

QXQM series planetary ball mill has four ball grinding tanks installed on one disc. When the turn disc rotates, the mill pots revolve on their own axis and make 360 degree rotation. And the balls in the tanks grind and mix samples in high speed movement. The product can smash and blend various products of different materials and granularity with dry or wet methods. Minimum granularity of ground samples can be as small as 0.1 micron meter. It is widely used in the fields of Geology, Mining, Metallurgy, Electronics, Construction Material, Ceramics, Chemical Engineering, Light Industry Medicine, Environmental Protection etc.

Reviews

There are no reviews yet.