ball mill is a quintessential piece of equipment in numerous industries, from mining and cement production to ceramics and pharmaceuticals.

Its function is to reduce the size of solid materials through a combination of impact and attrition. This chapter delves into the fundamental principles governing ball mill design, aiming to provide a comprehensive understanding of the factors influencing its performance and efficiency.

Basic Principles of Operation

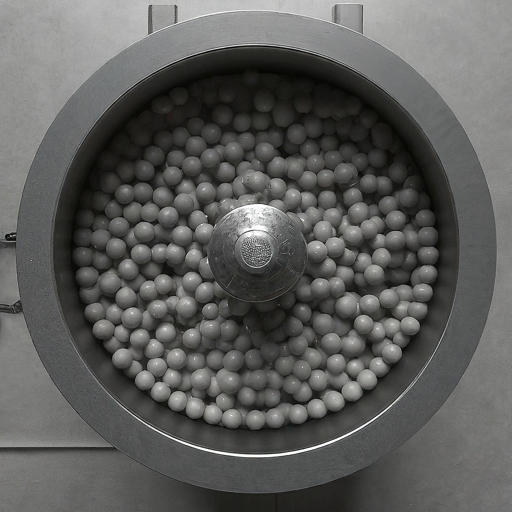

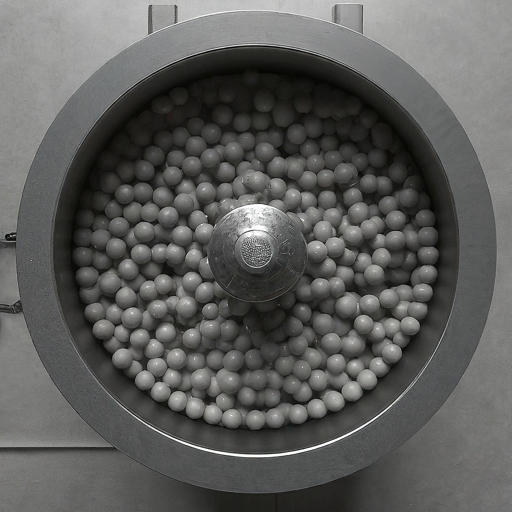

A ball mill is essentially a rotating cylindrical shell partially filled with grinding media, typically steel balls. As the mill rotates, the grinding media are lifted by the centrifugal force, cascading down to impact the material to be ground. This impact, coupled with the attrition caused by the grinding media rubbing against each other and the material, results in size reduction.

Source icon

Source icon

Critical Speed

A critical parameter in ball mill operation is the critical speed. It is defined as the rotational speed at which the grinding media just begin to centrifuge, forming a continuous annular layer on the mill's inner wall. Operating above the critical speed leads to a centrifuging action, while below it, a cascading action prevails. The choice of operating speed depends on the desired grinding conditions.

Source icon

Power Requirements

The power input to a ball mill is consumed in overcoming frictional losses, lifting the grinding media, and the actual grinding process. The power required for grinding is influenced by factors such as the feed size, desired product fineness, mill size, and the specific energy required for the material being ground.

Design Considerations

Mill Dimensions

The dimensions of a ball mill, including diameter and length, significantly impact its performance. A longer mill generally provides more grinding time, resulting in finer product. However, excessive length can lead to non-uniform grinding. The diameter influences the lifting height of the grinding media and the impact energy.

Source icon

Mill Liner Design

The mill liner plays a crucial role in the grinding process. It protects the mill shell from wear and influences the grinding action. The liner design, including its shape, material, and the arrangement of lifter bars, affects the grinding efficiency and power consumption.

Basic Principles of Operation

A ball mill is essentially a rotating cylindrical shell partially filled with grinding media, typically steel balls. As the mill rotates, the grinding media are lifted by the centrifugal force, cascading down to impact the material to be ground. This impact, coupled with the attrition caused by the grinding media rubbing against each other and the material, results in size reduction.

Source icon

Source icon

Critical Speed

A critical parameter in ball mill operation is the critical speed. It is defined as the rotational speed at which the grinding media just begin to centrifuge, forming a continuous annular layer on the mill's inner wall. Operating above the critical speed leads to a centrifuging action, while below it, a cascading action prevails. The choice of operating speed depends on the desired grinding conditions.

Source icon

Power Requirements

The power input to a ball mill is consumed in overcoming frictional losses, lifting the grinding media, and the actual grinding process. The power required for grinding is influenced by factors such as the feed size, desired product fineness, mill size, and the specific energy required for the material being ground.

Design Considerations

Mill Dimensions

The dimensions of a ball mill, including diameter and length, significantly impact its performance. A longer mill generally provides more grinding time, resulting in finer product. However, excessive length can lead to non-uniform grinding. The diameter influences the lifting height of the grinding media and the impact energy.

Source icon

Mill Liner Design

The mill liner plays a crucial role in the grinding process. It protects the mill shell from wear and influences the grinding action. The liner design, including its shape, material, and the arrangement of lifter bars, affects the grinding efficiency and power consumption.

Grinding Media

The choice of grinding media is critical. Factors to consider include the material's hardness, density, and wear resistance. The size and quantity of grinding media also impact the grinding efficiency. A suitable combination of media sizes can optimize the grinding process.

Feed and Discharge

The feed and discharge systems are essential components of a ball mill. The feed system should ensure uniform distribution of the material into the mill. The discharge system should effectively remove the ground product without affecting the grinding process.

Performance Evaluation

The performance of a ball mill is typically evaluated based on parameters such as product fineness, power consumption, and grinding efficiency. Various empirical and theoretical models are available to predict ball mill performance.

Bond's Work Index

Bond's work index is a widely used empirical parameter to estimate the power required for grinding a given material. It is determined through laboratory tests and can be used to predict the power consumption of a full-scale ball mill.

Source icon

Grinding Kinetics

Grinding kinetics studies the rate of particle size reduction in a ball mill. It involves analyzing the factors affecting the grinding rate, such as mill speed, media loading, and feed characteristics.

Scale-Up and Optimization

Scaling up a ball mill from laboratory to industrial scale requires careful consideration of various factors, including geometric similarity, power scaling, and material properties. Optimization of ball mill performance involves fine-tuning operating parameters and design variables to achieve desired product characteristics while minimizing energy consumption.

Conclusion

The design of a ball mill is a complex process involving numerous interrelated factors. A thorough understanding of the fundamental principles, coupled with practical experience, is essential for achieving optimal performance. By carefully considering the factors discussed in this chapter, engineers can design and operate ball mills efficiently for various applications.

Note: This is a general overview of ball mill design principles. A more in-depth analysis would require delving into specific aspects such as material properties, grinding mechanisms, and advanced modeling techniques. Additionally, practical case studies and experimental data would enrich the understanding of ball mill behavior.

Would you like to focus on a specific aspect of ball mill design, such as grinding media selection, liner design, or scale-up considerations?

Grinding Media

The choice of grinding media is critical. Factors to consider include the material's hardness, density, and wear resistance. The size and quantity of grinding media also impact the grinding efficiency. A suitable combination of media sizes can optimize the grinding process.

Feed and Discharge

The feed and discharge systems are essential components of a ball mill. The feed system should ensure uniform distribution of the material into the mill. The discharge system should effectively remove the ground product without affecting the grinding process.

Performance Evaluation

The performance of a ball mill is typically evaluated based on parameters such as product fineness, power consumption, and grinding efficiency. Various empirical and theoretical models are available to predict ball mill performance.

Bond's Work Index

Bond's work index is a widely used empirical parameter to estimate the power required for grinding a given material. It is determined through laboratory tests and can be used to predict the power consumption of a full-scale ball mill.

Source icon

Grinding Kinetics

Grinding kinetics studies the rate of particle size reduction in a ball mill. It involves analyzing the factors affecting the grinding rate, such as mill speed, media loading, and feed characteristics.

Scale-Up and Optimization

Scaling up a ball mill from laboratory to industrial scale requires careful consideration of various factors, including geometric similarity, power scaling, and material properties. Optimization of ball mill performance involves fine-tuning operating parameters and design variables to achieve desired product characteristics while minimizing energy consumption.

Conclusion

The design of a ball mill is a complex process involving numerous interrelated factors. A thorough understanding of the fundamental principles, coupled with practical experience, is essential for achieving optimal performance. By carefully considering the factors discussed in this chapter, engineers can design and operate ball mills efficiently for various applications.

Note: This is a general overview of ball mill design principles. A more in-depth analysis would require delving into specific aspects such as material properties, grinding mechanisms, and advanced modeling techniques. Additionally, practical case studies and experimental data would enrich the understanding of ball mill behavior.

Would you like to focus on a specific aspect of ball mill design, such as grinding media selection, liner design, or scale-up considerations?

Basic Principles of Operation

A ball mill is essentially a rotating cylindrical shell partially filled with grinding media, typically steel balls. As the mill rotates, the grinding media are lifted by the centrifugal force, cascading down to impact the material to be ground. This impact, coupled with the attrition caused by the grinding media rubbing against each other and the material, results in size reduction.

Source icon

Source icon

Critical Speed

A critical parameter in ball mill operation is the critical speed. It is defined as the rotational speed at which the grinding media just begin to centrifuge, forming a continuous annular layer on the mill's inner wall. Operating above the critical speed leads to a centrifuging action, while below it, a cascading action prevails. The choice of operating speed depends on the desired grinding conditions.

Source icon

Power Requirements

The power input to a ball mill is consumed in overcoming frictional losses, lifting the grinding media, and the actual grinding process. The power required for grinding is influenced by factors such as the feed size, desired product fineness, mill size, and the specific energy required for the material being ground.

Design Considerations

Mill Dimensions

The dimensions of a ball mill, including diameter and length, significantly impact its performance. A longer mill generally provides more grinding time, resulting in finer product. However, excessive length can lead to non-uniform grinding. The diameter influences the lifting height of the grinding media and the impact energy.

Source icon

Mill Liner Design

The mill liner plays a crucial role in the grinding process. It protects the mill shell from wear and influences the grinding action. The liner design, including its shape, material, and the arrangement of lifter bars, affects the grinding efficiency and power consumption.

Basic Principles of Operation

A ball mill is essentially a rotating cylindrical shell partially filled with grinding media, typically steel balls. As the mill rotates, the grinding media are lifted by the centrifugal force, cascading down to impact the material to be ground. This impact, coupled with the attrition caused by the grinding media rubbing against each other and the material, results in size reduction.

Source icon

Source icon

Critical Speed

A critical parameter in ball mill operation is the critical speed. It is defined as the rotational speed at which the grinding media just begin to centrifuge, forming a continuous annular layer on the mill's inner wall. Operating above the critical speed leads to a centrifuging action, while below it, a cascading action prevails. The choice of operating speed depends on the desired grinding conditions.

Source icon

Power Requirements

The power input to a ball mill is consumed in overcoming frictional losses, lifting the grinding media, and the actual grinding process. The power required for grinding is influenced by factors such as the feed size, desired product fineness, mill size, and the specific energy required for the material being ground.

Design Considerations

Mill Dimensions

The dimensions of a ball mill, including diameter and length, significantly impact its performance. A longer mill generally provides more grinding time, resulting in finer product. However, excessive length can lead to non-uniform grinding. The diameter influences the lifting height of the grinding media and the impact energy.

Source icon

Mill Liner Design

The mill liner plays a crucial role in the grinding process. It protects the mill shell from wear and influences the grinding action. The liner design, including its shape, material, and the arrangement of lifter bars, affects the grinding efficiency and power consumption.

Grinding Media

The choice of grinding media is critical. Factors to consider include the material's hardness, density, and wear resistance. The size and quantity of grinding media also impact the grinding efficiency. A suitable combination of media sizes can optimize the grinding process.

Feed and Discharge

The feed and discharge systems are essential components of a ball mill. The feed system should ensure uniform distribution of the material into the mill. The discharge system should effectively remove the ground product without affecting the grinding process.

Performance Evaluation

The performance of a ball mill is typically evaluated based on parameters such as product fineness, power consumption, and grinding efficiency. Various empirical and theoretical models are available to predict ball mill performance.

Bond's Work Index

Bond's work index is a widely used empirical parameter to estimate the power required for grinding a given material. It is determined through laboratory tests and can be used to predict the power consumption of a full-scale ball mill.

Source icon

Grinding Kinetics

Grinding kinetics studies the rate of particle size reduction in a ball mill. It involves analyzing the factors affecting the grinding rate, such as mill speed, media loading, and feed characteristics.

Scale-Up and Optimization

Scaling up a ball mill from laboratory to industrial scale requires careful consideration of various factors, including geometric similarity, power scaling, and material properties. Optimization of ball mill performance involves fine-tuning operating parameters and design variables to achieve desired product characteristics while minimizing energy consumption.

Conclusion

The design of a ball mill is a complex process involving numerous interrelated factors. A thorough understanding of the fundamental principles, coupled with practical experience, is essential for achieving optimal performance. By carefully considering the factors discussed in this chapter, engineers can design and operate ball mills efficiently for various applications.

Note: This is a general overview of ball mill design principles. A more in-depth analysis would require delving into specific aspects such as material properties, grinding mechanisms, and advanced modeling techniques. Additionally, practical case studies and experimental data would enrich the understanding of ball mill behavior.

Would you like to focus on a specific aspect of ball mill design, such as grinding media selection, liner design, or scale-up considerations?

Grinding Media

The choice of grinding media is critical. Factors to consider include the material's hardness, density, and wear resistance. The size and quantity of grinding media also impact the grinding efficiency. A suitable combination of media sizes can optimize the grinding process.

Feed and Discharge

The feed and discharge systems are essential components of a ball mill. The feed system should ensure uniform distribution of the material into the mill. The discharge system should effectively remove the ground product without affecting the grinding process.

Performance Evaluation

The performance of a ball mill is typically evaluated based on parameters such as product fineness, power consumption, and grinding efficiency. Various empirical and theoretical models are available to predict ball mill performance.

Bond's Work Index

Bond's work index is a widely used empirical parameter to estimate the power required for grinding a given material. It is determined through laboratory tests and can be used to predict the power consumption of a full-scale ball mill.

Source icon

Grinding Kinetics

Grinding kinetics studies the rate of particle size reduction in a ball mill. It involves analyzing the factors affecting the grinding rate, such as mill speed, media loading, and feed characteristics.

Scale-Up and Optimization

Scaling up a ball mill from laboratory to industrial scale requires careful consideration of various factors, including geometric similarity, power scaling, and material properties. Optimization of ball mill performance involves fine-tuning operating parameters and design variables to achieve desired product characteristics while minimizing energy consumption.

Conclusion

The design of a ball mill is a complex process involving numerous interrelated factors. A thorough understanding of the fundamental principles, coupled with practical experience, is essential for achieving optimal performance. By carefully considering the factors discussed in this chapter, engineers can design and operate ball mills efficiently for various applications.

Note: This is a general overview of ball mill design principles. A more in-depth analysis would require delving into specific aspects such as material properties, grinding mechanisms, and advanced modeling techniques. Additionally, practical case studies and experimental data would enrich the understanding of ball mill behavior.

Would you like to focus on a specific aspect of ball mill design, such as grinding media selection, liner design, or scale-up considerations?